Nearly one in five American businesses face fines each year due to improper hazardous material storage. Reliable protocols not only safeguard people but also shield your company from costly penalties and legal risks. Understanding how to properly assess, organize, and control hazardous substances can make all the difference for any American workplace. This guide lays out practical, step-by-step methods to protect your team, ensure regulatory compliance, and keep daily operations safe.

Table of Contents

- Step 1: Assess Storage Needs for Hazardous Materials

- Step 2: Select Appropriate Containers and Storage Units

- Step 3: Label and Segregate Hazardous Substances Clearly

- Step 4: Implement Safety Protocols and Access Controls

- Step 5: Inspect and Verify Storage Compliance Regularly

Quick Summary

| Key Insight | Explanation |

|---|---|

| 1. Conduct a Chemical Inventory | Document every hazardous material’s properties, quantity, and storage needs to ensure proper handling. |

| 2. Choose Suitable Containers | Select containers that match chemical types to prevent hazardous reactions and ensure safe storage. |

| 3. Clearly Label and Segregate | Use clear labels and segregation strategies to avoid dangerous chemical interactions and maintain safety. |

| 4. Implement Safety Protocols | Establish access controls, training, and emergency procedures to protect personnel and manage risks effectively. |

| 5. Perform Regular Inspections | Schedule consistent inspections of storage conditions to identify issues and ensure compliance with safety standards. |

Step 1: Assess Storage Needs for Hazardous Materials

Successfully storing hazardous materials starts with a thorough and systematic assessment of your specific storage requirements. This critical first step involves identifying, categorizing, and understanding the unique characteristics of the hazardous substances in your possession.

Begin by conducting a comprehensive chemical inventory and hazard determination, as recommended by OSHA’s guidelines. This means meticulously documenting every hazardous material present, including its physical state, chemical properties, and potential interaction risks. Pay close attention to each substance’s specific storage needs such as temperature sensitivity, reactivity with other chemicals, and potential environmental impact. The USDA’s Everyday Hazmat User’s Training Guide emphasizes evaluating storage requirements based on distinct material classes like flammable liquids, combustible materials, and corrosive substances.

Your inventory should include critical details such as chemical name, quantity, storage compatibility, and specific handling instructions. Group similar materials together based on their chemical characteristics and potential interaction risks to minimize potential chemical reactions or safety hazards.

Pro Tip: Create a color coded tracking system for your hazardous materials inventory that allows for quick visual identification of storage requirements and potential interaction risks.

Here’s a reference table summarizing key hazardous material classes and their primary storage considerations:

| Material Class | Primary Storage Concern | Common Container Type |

|---|---|---|

| Flammable Liquids | Fire and vapor risks | Sealed metal safety cans |

| Corrosive Substances | Material degradation | Resistant plastic or glass |

| Oxidizers | Reactivity with combustibles | Segregated metal containers |

| Toxic Chemicals | Inhalation/contact exposure | Airtight plastic or glass |

| Compressed Gases | Explosion under heat | High-pressure metal cylinders |

Step 2: Select Appropriate Containers and Storage Units

Selecting the right containers and storage units is crucial for safely managing hazardous materials. Your choice will directly impact the safety, compliance, and long term stability of your potentially dangerous substances.

According to the USDA’s Everyday Hazmat User’s Training Guide, specific container requirements vary based on the type of hazardous material. For flammable and combustible liquids, specialized metal drums and safety cans are recommended to prevent potential chemical reactions or accidental releases. When selecting storage units, consider factors like material compatibility, temperature resistance, ventilation, and structural integrity. Different hazardous materials require different storage approaches metal containers work best for some chemicals, while specialized plastic or glass containers might be ideal for others.

Ensure your chosen containers are clearly labeled with the specific contents, hazard class, and any necessary warning symbols. Look for containers that are professionally rated for chemical storage, feature tight sealing mechanisms, and have appropriate protective coatings that prevent chemical degradation. Segregate incompatible materials using separate storage units to minimize potential dangerous interactions.

Pro Tip: Always inspect storage containers quarterly for signs of wear, corrosion, or potential structural weaknesses that could compromise hazardous material containment.

Step 3: Label and Segregate Hazardous Substances Clearly

Properly labeling and segregating hazardous substances is a critical safety procedure that prevents potential chemical interactions and ensures workplace safety. This step requires meticulous attention to detail and a systematic approach to managing potentially dangerous materials.

OSHA’s Hazard Communication guidance emphasizes the critical importance of clear labeling and strategic segregation to minimize risks of dangerous chemical reactions. Each hazardous substance must be marked with comprehensive information including chemical name, hazard classification, potential health risks, and necessary handling precautions. Use standardized color coding, clear text, and internationally recognized hazard symbols to make identification instantaneous. The USDA’s Everyday Hazmat User’s Training Guide recommends creating a comprehensive segregation matrix that groups chemicals based on their compatibility and potential interaction risks.

When segregating materials, create distinct storage zones that prevent incompatible substances from being stored near each other. This means separating oxidizers from flammable liquids, keeping acids and bases apart, and ensuring reactive chemicals are isolated. Implement a clear visual mapping system in your storage area that uses color coded zones, physical barriers, and explicit signage to prevent accidental mixing or cross contamination.

Pro Tip: Develop a digital tracking system that logs each hazardous material’s exact location, ensuring real time accountability and quick emergency reference.

Step 4: Implement Safety Protocols and Access Controls

Safety protocols and access controls are your critical line of defense in managing hazardous materials. This step involves creating comprehensive systems that protect both personnel and your facility from potential chemical risks and unauthorized interactions.

OSHA’s HAZWOPER standard mandates robust emergency response plans that go beyond basic storage guidelines. Develop a multi layered access control system that includes restricted entry points, secure locks, electronic monitoring, and detailed visitor logging procedures. Require all personnel to wear appropriate personal protective equipment and maintain comprehensive training records for anyone authorized to enter hazardous material storage areas. The USDA’s Everyday Hazmat User’s Training Guide emphasizes creating clear documentation trails and maintaining strict accountability for all interactions with hazardous substances.

Establish clear emergency response protocols that outline precise steps for potential chemical spills, exposure incidents, and evacuation procedures. Create visible emergency contact information, install specialized safety equipment like eyewash stations and chemical shower areas, and conduct regular safety drills to ensure all team members understand critical response mechanisms. Implement a comprehensive training program that includes both initial certification and recurring safety education to keep all staff updated on the latest hazardous material handling techniques.

Pro Tip: Develop a color coded badge system that instantly communicates each employee’s level of hazardous material handling certification and authorized access zones.

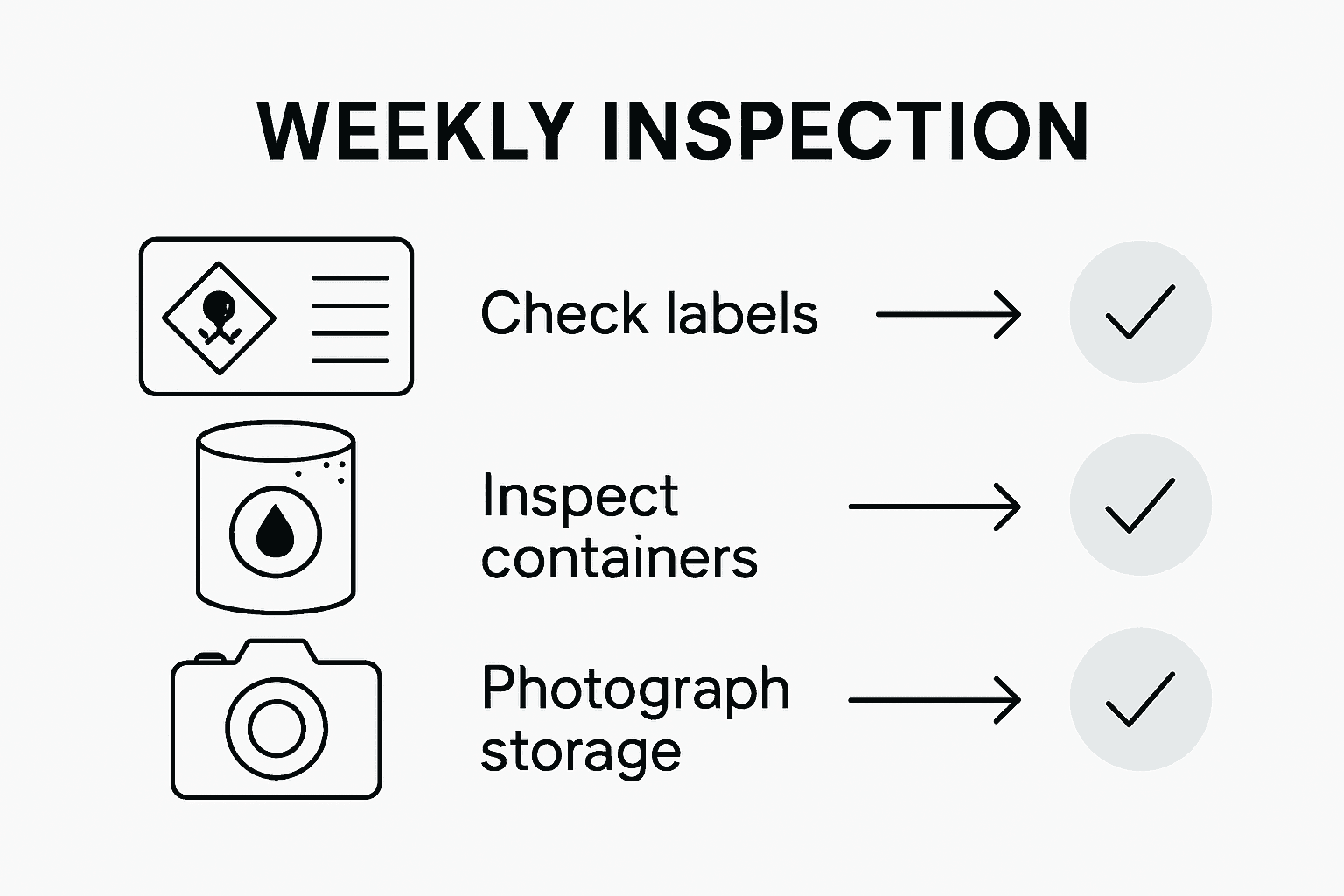

Step 5: Inspect and Verify Storage Compliance Regularly

Regular inspections are the backbone of maintaining safe hazardous material storage. By systematically verifying your storage conditions, you protect your facility, employees, and environment from potential chemical risks.

FedCenter guidelines mandate weekly inspections of hazardous waste storage areas to ensure stringent safety standards. Develop a comprehensive inspection checklist that covers critical elements including container integrity, seal conditions, labeling accuracy, and potential signs of corrosion or damage. The USDA’s Everyday Hazmat User’s Training Guide recommends documenting each inspection with detailed notes tracking the condition of storage containers and any emerging concerns.

Create a standardized inspection protocol that includes photographing storage areas, measuring container conditions, checking temperature and humidity levels, and verifying that all safety equipment remains functional. Assign specific team members responsible for conducting these inspections and establish clear escalation procedures for reporting any detected irregularities. Implement a digital tracking system that timestamps each inspection and generates automatic alerts for potential compliance issues or maintenance requirements.

Pro Tip: Rotate inspection responsibilities among trained team members to ensure fresh eyes and multiple perspectives during compliance verification.

This summary table highlights essential inspection tasks for hazardous material storage compliance:

| Inspection Task | Frequency | Purpose |

|---|---|---|

| Container integrity check | Weekly | Detect leaks or structural weaknesses |

| Labeling accuracy verification | Weekly | Ensure correct hazard identification |

| Environmental monitoring | Weekly | Track temperature and humidity levels |

| Safety equipment test | Monthly | Confirm eyewash stations and alarms work |

| Documentation review | Monthly | Track inspection history and corrections |

Ensure Safe and Compliant Hazardous Material Storage with Expert Solutions

Storing hazardous materials safely and legally demands more than just knowledge it requires dependable storage containers and expert handling strategies designed to protect your people and property. Key challenges include selecting the right containers, proper labeling and segregation, and maintaining strict safety protocols to avoid costly accidents or regulatory issues. Our solutions address these pain points by offering high-quality, chemical-resistant Storage Containers tailored for hazardous material needs and long-term durability.

Don’t leave hazardous material storage to chance. Explore our trusted Long-Term Storage Solutions to secure your operations and comply with strict safety standards. Act today to protect your commercial fleet and workplace. Visit Apple Truck & Trailer now for dependable equipment and service—because safe storage starts with the right partner.

Frequently Asked Questions

How do I assess my storage needs for hazardous materials?

To assess your storage needs for hazardous materials, start by conducting a thorough chemical inventory. Document each substance’s physical state, chemical properties, and specific storage requirements to ensure safe handling.

What types of containers should I use for hazardous materials?

Select containers based on the type of hazardous material you are storing. For example, flammable liquids are best kept in sealed metal safety cans, while corrosive substances require resistant plastic or glass containers to prevent degradation.

How should I label hazardous materials for safe storage?

Label each hazardous material with clear information including chemical name, hazard classification, and handling precautions. Use standardized color coding and recognizable hazard symbols to facilitate quick identification and ensure that all labels are legible and up to date.

What safety protocols should I implement for hazardous material storage?

Implement a multi-layered safety protocol that includes restricted access areas, proper personal protective equipment, and emergency response plans. Require regular training for all employees who handle hazardous materials to ensure they understand safety measures and emergency procedures.

How often should I inspect hazardous material storage areas?

Conduct weekly inspections of hazardous material storage areas to verify compliance with safety regulations. Use a detailed checklist to assess container integrity, labeling accuracy, and potential environmental risks to maintain safety and proper storage conditions.

What should I do if I find compliance issues during inspections?

If you identify compliance issues during inspections, take immediate corrective action to address any problems. Document these issues and follow up with re-inspections and necessary updates to your storage practices within 30 days.